CNC Turning

CNC Turning

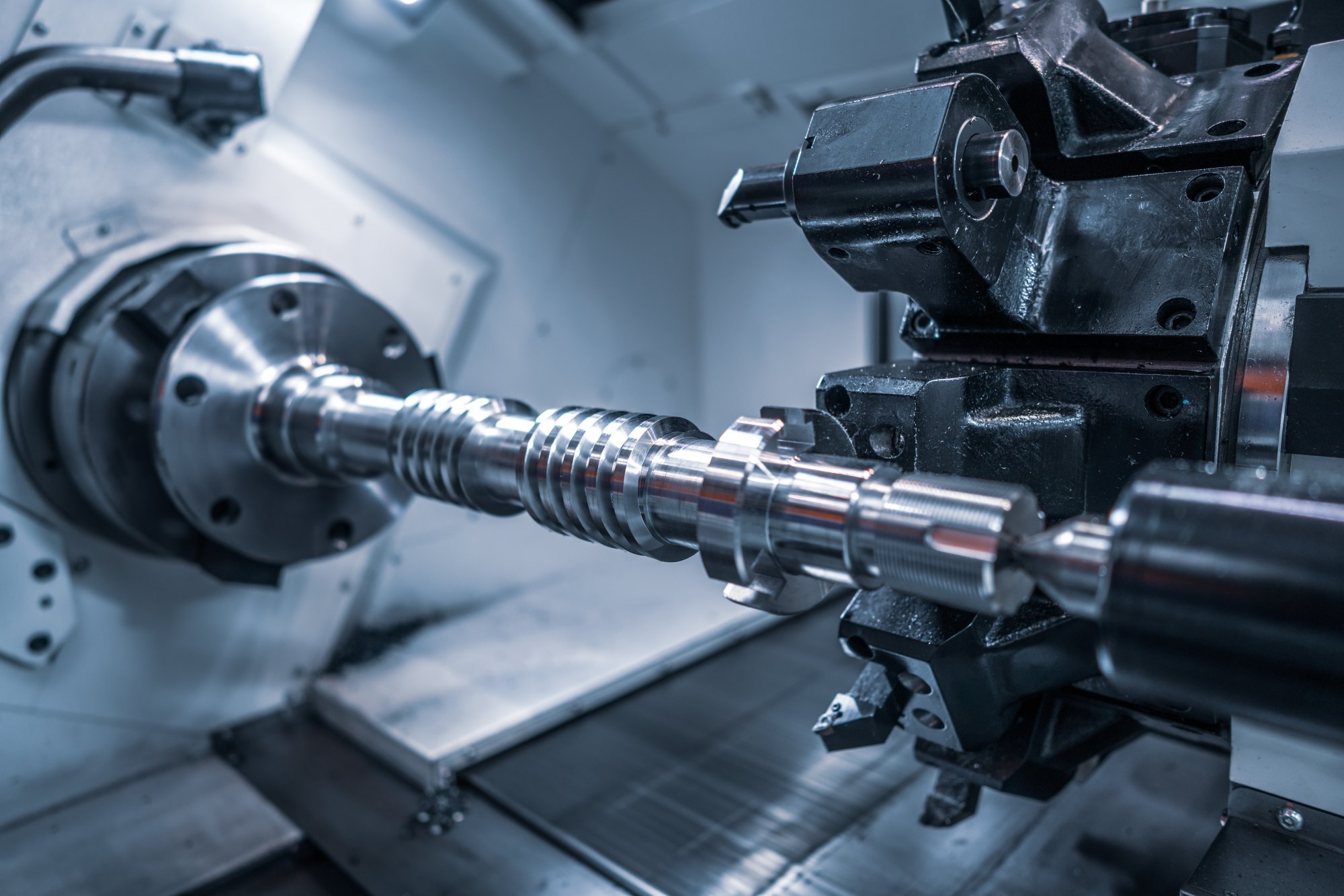

At DCS Tech Industries, turning is a fundamental machining process that plays a crucial role in our manufacturing capabilities. Turning involves the removal of material from a rotating workpiece using a cutting tool. This process is essential for creating cylindrical parts with precise dimensions and smooth finishes, making it ideal for various applications across multiple industries.

How Turning Works

Turning is performed on a lathe, a machine that rotates the workpiece while a cutting tool is fed into it. The lathe can move the tool along various axes to shape the material into the desired form. The primary motion is the rotation of the workpiece, which allows the cutting tool to remove material in a controlled manner, producing symmetrical components with high accuracy.

There are two main types of turning operations:

Straight Turning: This involves removing material along the length of the workpiece to produce a uniform diameter. It is commonly used to create shafts, rods, and other cylindrical parts.

Complex Turning: For more intricate shapes, such as threads, grooves, and tapered features, complex turning techniques are employed. CNC (Computer Numerical Control) lathes can automate these operations, providing high precision and repeatability.

Advantages of Turning

Turning offers several advantages that make it a preferred machining process for producing cylindrical components:

Precision: Turning is known for its ability to achieve high precision and tight tolerances. The process is capable of producing parts with exact dimensions and smooth surface finishes, essential for applications requiring strict quality standards.

Efficiency: The rotational motion of the workpiece allows for continuous cutting, making turning a highly efficient process for both small and large production runs. CNC lathes further enhance efficiency by automating complex operations and reducing setup times.

Versatility: Turning can handle a wide range of materials, including metals, plastics, and composites. This versatility makes it suitable for various industries, from automotive and aerospace to medical devices and consumer goods.

Surface Finish: The cutting tools used in turning can produce smooth surface finishes, reducing the need for additional finishing processes. This is particularly valuable for parts that require a high-quality surface appearance.

Applications of Turning

Turning is employed in numerous industries to produce components with cylindrical shapes and precise specifications:

Automotive: In the automotive industry, turning is used to manufacture parts such as engine components, transmission shafts, and suspension components. The precision and durability of turned parts are critical for ensuring the performance and reliability of vehicles.

Aerospace: Aerospace applications require components with tight tolerances and high strength. Turning is used to produce parts such as landing gear components, turbine blades, and structural fittings, all of which must meet rigorous performance standards.

Medical Devices: The medical industry relies on turning for producing components like surgical instruments, implants, and diagnostic equipment. The high precision and quality of turned parts are essential for the safety and effectiveness of medical devices.

Industrial Machinery: Turning is also used in the manufacturing of parts for industrial machinery, including gears, bearings, and housings. The ability to produce high volumes of precise components makes turning a valuable process for industrial applications.

Quality and Expertise

At DCS Tech Industries, we are committed to delivering high-quality turned components that meet the highest standards. Our experienced machinists utilize advanced lathes and cutting tools to ensure precision and consistency in every part we produce. From initial design to final inspection, our rigorous quality control processes guarantee that each component meets or exceeds our clients’ specifications.